In today's fiercely competitive market, leveraging industrial shed efficiency is paramount for enterprises of all sizes. A well-optimized shed can substantially boost productivity, reduce operational costs, and ultimately drive success. Key considerations for achieving this optimization include streamlining workflow processes, incorporating advanced storage solutions, and utilizing available space. By carefully addressing these factors, industrial sheds can be transformed into high-performing hubs that contribute significantly to the overall success of any organization.

The Significance of Structural Integrity in Industrial Shed Design

Industrial sheds necessitate meticulous designing to ensure robust structural integrity. The structural skeleton must effectively withstand environmental factors, including heavy machinery, stored goods, climatic events. Architects leverage engineering principles to determine the required load-bearing capacity of the shed's components.

Moreover, architectural choices play a crucial role in achieving optimal performance. Factors like roof slope, wall height, foundation type must be carefully assessed to optimize the shed's lifespan.

Improving Air Flow in Industrial Sheds Best Practices for Air Quality

Ensuring optimal air quality within industrial sheds is paramount for the safety of workers and the quality of equipment. Effective ventilation systems are essential for eliminating harmful particulates such as get more info dust, fumes, and gases that can congregate in these enclosed spaces.

Implement a multi-pronged approach to ventilation by combining natural airflow with mechanical systems like blowers. Strategically position intake and exhaust vents to create a continuous flow of fresh air.

- Periodically monitor ventilation systems for functionality and resolve any issues promptly.

- Assess the use of air filtration systems to capture fine particles.

- Instruct workers on the importance of ventilation and proper handling procedures.

Maximizing Productivity with Lighting Solutions in Industrial Environments

In demanding industrial shed environments, optimized lighting is paramount to ensuring superior productivity and worker comfort. Inadequate lighting can lead to reduced output, slowing efficiency and potentially compromising workplace safety. To resolve these challenges, employers should utilize a range of advanced lighting options.

- LED fixtures offer enhanced energy efficiency and durability, while intelligent lighting systems can dynamically adjust to varying workloads.

- Skylights can greatly reduce reliance on artificial power, creating a healthier and stimulating work environment.

- Spectral distribution should be strategically chosen to match the specific needs of each work zone within the industrial shed.

By utilizing a comprehensive lighting strategy, industrial sheds can maximize productivity, optimize worker safety, and reduce energy costs.

Effects of Automated Systems in Warehouses

The adoption of automation technologies within industrial shed operations is fundamentally changing the landscape. From material handling and logistics to quality control and production, automated systems are increasing efficiency. This trend presents both opportunities for operators, as they must evolve their workforce skills and tactics to effectively leverage the power of automation. Moreover, the rise of collaborative robots (cobots) is transforming the traditional lines between human and machine, creating a integrated work environment.

- For instance, automated guided vehicles (AGVs) are improving material movement within sheds, while robotic arms are performing repetitive tasks with precision and speed.

- As a result, labor costs can be lowered, and overall productivity can be substantially increased.

- Nevertheless, it is crucial for operators to provide continuous learning opportunities to ensure a smooth adaptation and optimize the full potential of automation.

Sustainable Construction Materials for Eco-Friendly Industrial Sheds

Industrial sheds require robust and durable construction materials to withstand the rigors of industrial operations. But, traditional building supplies often come with a hefty environmental impact. Thankfully, a growing selection of sustainable construction choices is accessible to create eco-friendly industrial sheds that are both resilient and sustainably responsible.

Timber, a renewable material, can be used for framing, decking, and cladding, absorbing carbon dioxide during its growth cycle. Steel made from recycled materials reduces the need for new extraction. Additionally, insulating materials like hemp fiber or cork offer excellent thermal efficiency, minimizing energy consumption.

By embracing these sustainable construction techniques, industries can erect industrial sheds that are not only functional but also decrease their environmental effect. This shift towards eco-friendly construction represents a crucial step in creating a more sustainable future.

Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Danielle Fishel Then & Now!

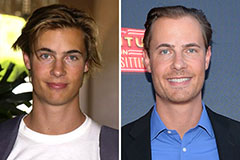

Danielle Fishel Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Kane Then & Now!

Kane Then & Now!